Driver Industrial Safety® Brands

Brands

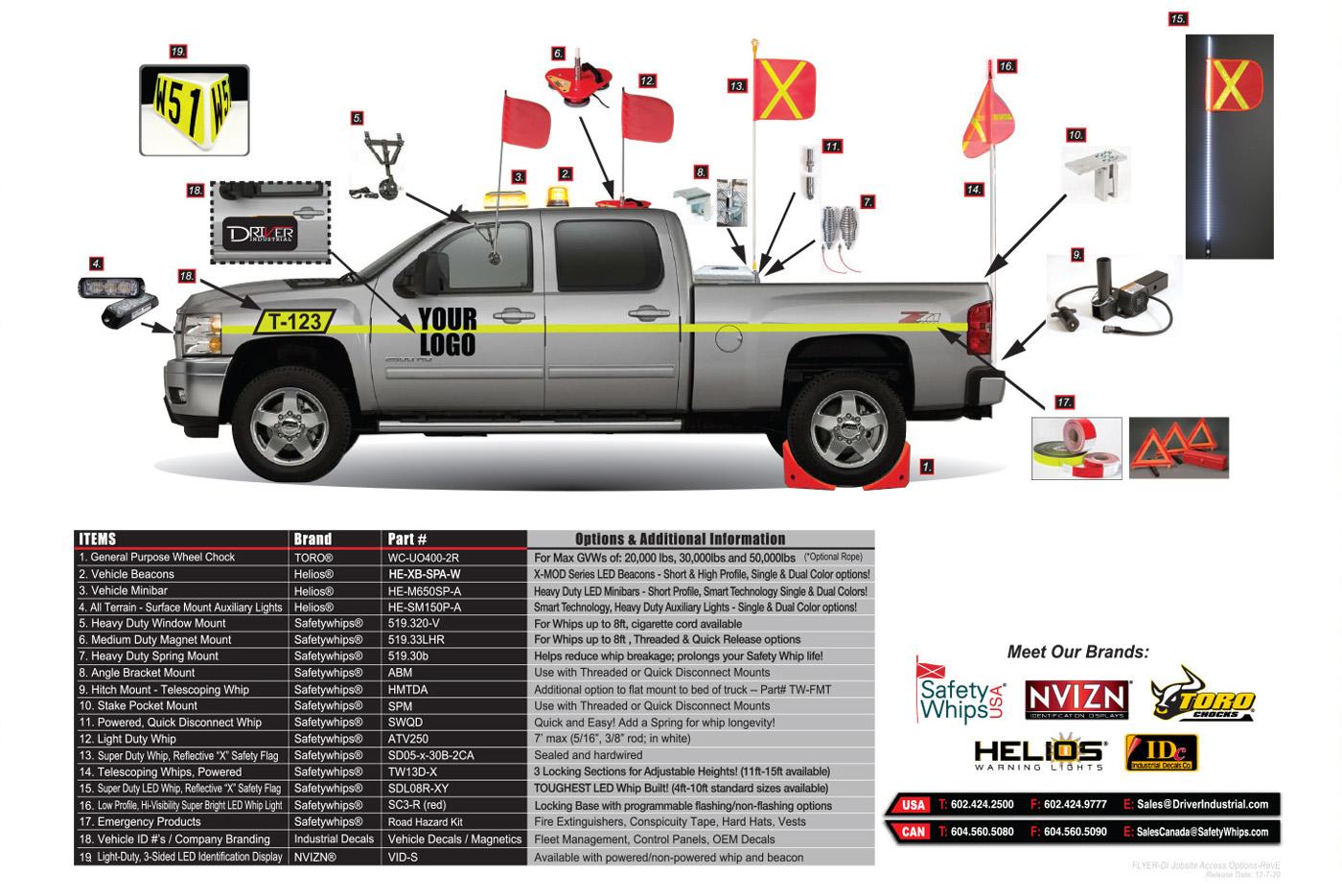

Jobsite Access Options

TORO® Wheel Chocks

- TORO® Wheel Chocks are the most dependable wheel chocks in the industry.

- Field Tested in harsh environments for over 10 years.

- Large Selection of wheel chocks offered to provide quality safety for a variety of General Purpose Vehicles and Heavy-Duty Equipment.

- Wheel Chocks are manufactured in the United States (USA).

- Wheel Chocks are 3rd-party tested to meet the compliance standards for MSHA, OSHA, NFPA, DOT, SAE, and ANSI.

- Tough Urethane Construction.

- User Safety and Proper Chocking Procedures Guides available.

TORO® Wheel Chocks – Get it Right the First Time.

We pride ourselves with the precision and rugged construction of TORO® Wheel Chocks which are Manufactured in the USA. Driver Industrial Safety’s TORO® Wheel Chocks team of project managers and engineers are continuously working with various industry safety experts to ensure we design the most dependable & visible products in our market; regardless of the severe weather conditions and working conditions that may ensue. We ensure our TORO® Wheel Chocks work with a broad range of ground vehicles, underground vehicles, heavy equipment, commercial, firefighting, and military vehicles. Driver Industrial has the wheel chocks you require to safely secure your vehicle and meet necessary compliance standards; from a completely loaded 400 Ton haul truck to a small service trailer.

TORO® Wheel Chocks are Industrial Strength.

The General Purpose line of TORO® Wheel Chocks are engineered for quick and secure installation typically used for land vehicles such as trailers, pickups, utility vehicles, dual axle vehicles, and other standard size vehicles. Constructed with tough Urethane for lightweight and easy mobility, high visibility ANSI compliant safety colors and holes for mounting with rope, chains, or mounting brackets. All model styles are 3rd-party tested for compliance and supporting GVW’s (Maximum Gross Vehicle Operating Weight) ranging from 15 Ton (30,000 lb. or 13,607 kg.) to 35 Ton (70,000 lb. or 31,751 kg.).

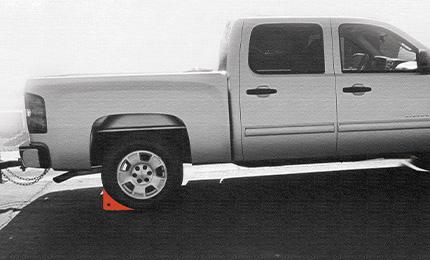

Uphill Grade: TORO® WC-UO400 15 Ton (13,607 kg)

Wheel Chocks on Pickup truck

Downhill Grade: TORO® WC-UO600 25 Ton (22,679 kg)

Wheel Chocks on heavy duty Diesel truck

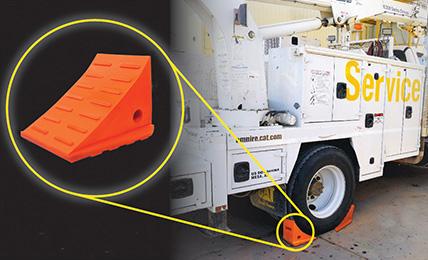

Level Grade: TORO® WC-UO650 35 Ton (31,751 kg)

Wheel Chocks on Utility Service vehicle

The Heavy Equipment line of TORO® Wheel Chocks are heavy duty and engineered to safely secure heavy equipment vehicles (haul trucks, loaders, cranes, fire department vehicles, large military trucks, and heavy underground mining vehicles). Constructed with tough Urethane for lightweight and easy mobility with built-in strong carrying handle on the back side of each wheel chock. These large chocks are highly visible (ANSI compliant safety colors) with user-friendly mounting brackets for quick and secure loading on the vehicle. All model styles are 3rd-party tested for compliance with Maximum Payload Capacities ranging from 70 Ton (140,000 lb. or 63,502 kg.) to 400 Ton (800,000 lb. or 362,873 kg.).

Downhill Grade: TORO® WC-UY700 70 Ton (63,502 kg)

Wheel Chocks on mine support vehicle

Level Grade: TORO® WC-UY750 165 Ton (149,685 kg)

Wheel Chocks on construction site Loader

Level Grade: TORO® WC-UY910 400 Ton (725,747 kg)

Wheel Chocks on minesite Haul Truck

Driver Industrial Safety’s TORO® Wheel Chocks Exceed Expectations.

TORO® Wheel Chocks surpass quality standards and comply with multiple industry safety requirements including MSHA (Mine Safety and Health Administration), OSHA (Occupational Safety and Health Administration), NFPA (National Fire Protection Agency), DOT (Department of Transportation), SAE (Society of Automotive Engineers), and ANSI (American National Standards Institute) standards to ensure a safe working environment at all times. We offer a variety of structure styles to serve specific industry needs as well as ANSI compliant safety color and custom color options for added support in providing safe and creative solutions for any type of vehicle or heavy equipment on site.

TORO® Wheel Chocks

Heavy Equipment Wheel Chocks

- Maximum Load Capacities of 70 Ton, 165 Ton, 255 Ton, 400 Ton.

- Tough Urethane construction.

- ANSI compliant color written guidelines for land vehicles with proper

chocking procedures. - Strong Built-in rear carrying handles.

- Holes for mounting brackets.

Heavy Equipment

TORO® WC-UY910 400 Ton (362,874 kg)

shown

General Purpose Wheel Chocks

- Maximum Load Capacities of 15 Ton, 25 Ton, 30 Ton, 35 Ton.

- Lightweight tough Urethane construction.

- Molded-in rear carrying handles.

- Multiple High Visibility safety colors available.

- Holes for rope, chains & mounting brackets.

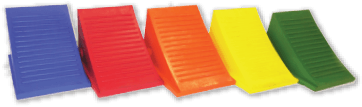

- General Purpose Wheel Chocks are available in Multiple Colors

upon request:- Standard colors include: Yellow, Orange, Blue, Green, Red.* custom colors also available.

- Color coordination can help with site safety and job management.

General Purpose

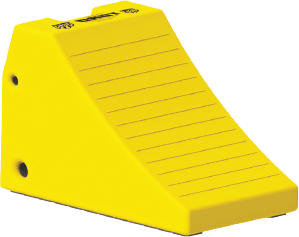

TORO® WC-UO400 15 Ton (13,607 kg)

shown

Custom Colors Available Upon Request!

Dual Axle Wheel Chocks available with a Maximum Load Capacities of 10 Ton (20,000 lb. or 9,071 kg.). Revolutionary design suitable for most Dual Axle Platforms: Caravans, RV’s, Horse Trailers, Boat Trailers, Box Trailers.*

TORO® Wheel Chocks Type, Size, Quantity Used

Must Properly Suit Your Application Needs.

Your vehicle, environment, payload, and your maximum Gross Vehicle Weight (GVW) will determine the type of wheel chock for your application. See our Chocking Procedures for land vehicle use which provide Chocking Diagrams to provide end users with direction on positioning chock on either uphill, downhill or level grade placement of chocks for various applications on vehicles or heavy equipment such as vehicles with 2 or more axels, articulated trucks, trucks up to 255 tons, and trucks over 255 tons.

QUALITY guidance documents are available to ensure the success in meeting each vehicle’s specific requirements:

- Gross Operating Weight (GVW)

- Maximum Load Capacity

- Tire Size (Diameter)

- Chock models & proper chocking – factoring environmental conditions, ground surfaces and grade/level of ground surface

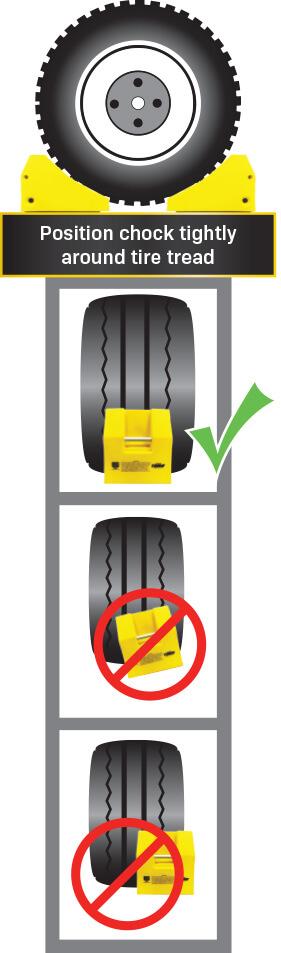

Before Using TORO® Wheel Chocks…

Ensure end users are educated on the correct use of wheel chocks. We want to set some guidelines by preparing some basic user safety recommendations to avoid potential safety issues of not using wheel chocks, and to ensure they are being used correctly. Wheel chocks not used properly such as the wrong size chock; or using an incorrect quantity of chocks – can create safety issues. There are many conditions that only require 2 chocks per vehicle, and some may need 4 chocks per vehicle. Prior to using wheel chocks a user must take several aspects into consideration. The end user should be required to consider these several aspects which may alter the wheel chock’s performance:

- Gross Vehicle Operating Weight

End Users must understand the GVW of the vehicle to determine the necessary wheel chock for your specific requirements. - Maximum Load Capacity

Maximum Load Capacity is based per chock. Each chock is designed to handle a certain amount of Tonnage. MINIMUM of (2) chocks required per vehicle. - Tire Size

End Users must identify the tire diameter of the vehicle to select the correct wheel chock needed. - Tire Pressure

Ensure your tire pressure is inline as changing and shifting pressures can happen naturally with changes in the environment, as the air expands and contracts. - Ground Surface Level or Grade

End Users must be aware of the environmental conditions and ground surface the tires are exposed to, whether it is firm, soft, wet, dry, icy, frozen. Driver Industrial manufactures wheel chocks for all applications, with optional cleated pads available for additional traction.

When selecting the most appropriate wheel chock for each application, numerous combinations of circumstances must be considered. You cannot roughly assume the same wheel chocks will hold the same vehicle every time, you need to test a pair of wheel chocks as specified on a certain grade in each environment and circumstance for every situation. Each location or job site should perform careful testing to ensure ethe specific wheel chocks meet their needs at each site location to ensure the chocks meet their requirements. Wheel chocks require not much or no maintenance but do require regular visual examination for cracking, chipping, and any other noticeable concerning physical malfunctions to indicate the need for replacement.

ATTENTION! Wheel Chock Users…

IMPORTANT SAFETY WARNINGS AND INSTRUCTIONS:

Wheel chocks are extremely effective safety tools providing optimum security when used correctly. Users must comply with all warnings, guidelines and instructions for land vehicles which are provided with each TORO® product. Wheel chocks MUST BE used in pairs, positioned downhill firmly against the tire and below the truck’s center of gravity. Meaning, place a chock in front of both front tires if the truck is disabled and traveling down a grade, and in traveling up a grade while disabled place a chock in back of both rear tires of the truck. If the direction of the grade cannot be determined chock the front and back of one wheel. In severe conditions, it’s necessary to use multiple pairs of chocks. Wheel chocks MUST BE positioned firmly and squarely against the center of the tire tread. If not properly positioned, the wheel chock will not be effective to it’s expected potential. These are generally accepted chocking procedures, and it is the responsibility of the end user to make the final determination of how the vehicle should properly be chocked based on the provided circumstances.

Our main goal is to inform and educate users on how to properly use TORO® wheel chocks. Testing & qualification is required for individual vehicles and for correct product selection to meet site requirements. Many factors MUST BE considered before selecting and using our wheel chocks. Numerous variables occur which can a ect the wheel chocks performing up to their potential; including but not limited to:

- Wheel Size or Tire Diameter (Check out our Wheel Chock Selection Guide)

- Maximum Gross Vehicle Operating Weight (Check out our Wheel Chock Selection Guide)

- Grade or Level of the ground surface

- Radial Tires vs. Bias Ply tires must be taken into consideration. Radial tires by design flex and deflect more than a bias-ply tire due to not having as many plies or body cords on the sidewall which allows radial tires to flex more. This flexibility provides a smooth ride due to the larger more stable ground contact area – which enables the tire to wrap up around the wheel chock, decreasing the chock’s efficiency.

- Changing tire pressures occur with fluctuations in the natural environment

- State or current condition of the ground surface (i.e. frozen, icy, wet, dry, firm, soft and pliable).

Wheel Chock Basics to Consider:

Advised Gross Vehicle Operating Weight (GVW) is a guide only. This will vary due to various environmental factors. Please complete an adequate risk assessment in your environment before using the chocks. Testing and qualification is required for individual vehicles and for correct product placement. Advised GVW is a guide only. This will vary due to environmental factors. Please complete an adequate risk assessment before using chocks. DO NOT use chocks if chocks are damaged. Perform regular inspections looking for cracking, chipping, and any other noticeable concerning physical malfunctions.

Tire Size

IDENTIFY the tire diameter of the

vehicle to select the correct wheel

chock needed.

Gross Vehicle Operating Weight

MUST understand the GVW of the vehicle

to determine the necessary wheel chock

for your specific requirements.

Maximum Load Capacity

Based per chock. Each chock is designed to

handle a certain amount of Tonage. MINIMUM

of (2) chocks required per vehicle.

Ground Surface

BE AWARE of the environmental conditions

and ground surface the tires are exposed to.

Our chocks adhere to all types of surfaces.

OSHA Requires:

1910.178(k)… (1) The brakes of highway trucks shall be set and wheel chocks placed under the rear wheels to prevent the trucks from rolling while they are boarded with powered industrial tracks.

1910.178(m)… (7) Brakes shall be set and wheel blocks shall be in place to prevent movement of trucks, trailer, or railroad cars while loading or unloading. Fixed jacks may be necessary to support a semitrailer during loading or unloading when the trailer is not coupled to a tractor.

1910.111(f)… (9) Chock blocks. At least two chock blocks shall be provided. These blocks shall be placed to prevent rolling of the vehicle whenever it is parked during loading and unloading operations.

MSHA Requires:

MSHA Standard for Surface Operations

30 CFR Subsection 56.14207 – Parking procedures for unattended equipment.

Mobile equipment shall not be left unattended unless the controls are placed in the park position and the parking brake, if provided, is set. When parked on a grade, the wheels or tracks of mobile equipment shall be either chocked or turned into a bank.

MSHA Standard for Underground Mines

30 CFR Subsection 57.14207 – Parking procedures for unattended equipment.

Mobile equipment shall not be left unattended unless the controls are placed in the park position and the parking brake, if provided, is set. When parked on a grade, the wheel chocks or tracks of mobile equipment shall be either chocked or turned into a bank.

MSHA Standard for Procedures During Repairs or Maintenance

30 CFR Subsection 56.14105 – Repairs or maintenance of machinery or equipment shall be performed only after the power is off, and the machinery or equipment blocked against hazardous motion. Machinery or equipment motion or activation is permitted to the extent that adjustments or testing cannot be performed without motion or activation, provided that persons are effectively protected from hazardous motion.

Wheel Chock Performance Comparison

Urethane vs. Aluminum Wheel Chocks

Urethane Wheel Chocks are:

- Manufactured with high visibility orange and yellow safety colors

- Not painted with safety colors like metal; The chocks will not chip, peel, or get scratched up

- Formed from a high impact absorbing urethane

- Not at risk of tire puncture or tears

- Simple to carry with Built-in and Molded-in carrying handles (no sharp or harsh edges)

- Non-conductive – not able to conduct electricity

- Not at risk for thieves to steal chocks to be sold as scrap metal

- User guidelines molded into wheel chock in English on most of our Series, and in three languages on the 910 Series: English, Spanish and French

- Optional anti-skid cleated rubber traction cleated pads

Urethane vs. Wood Wheel Chocks

Urethane Wheel Chocks are:

- Completely Maintenance free in comparison, only inspection required routinely

- Extremely resistant to Abrasion and Harsh Weather – will not start splitting, rotting, or cracking like wood

- Simple to carry with Built-in and Molded-in carrying handles (no sharp or harsh edges)

- Especially resistant to fuels, oils, and solvents

- Not painted with safety colors like wood; so the chocks will not flake off, chip, peel, or get scratched up

- Tough weather resistant Urethane construction is lightweight and high impact absorbing

- Compliant with Aviation – Foreign Object Debris (FOD)

- Lightweight, and will not get waterlogged and heavy like wood

- Offered with anti-skid cleated rubber traction pads to ensure to avoid delamination due to corrosion

- Optional Mounting Brackets available

Urethane vs. Rubber Wheel Chocks

Urethane Wheel Chocks are:

- Extremely Lightweight in comparison

- Designed and Manufactured to have a much longer lifespan than rubber competition

- Extremely resistant to Abrasion and Harsh Weather – will not start chipping, dry-rotting, or cracking like rubber

- High-level load bearing capability

- Especially resistant to fuels, oils, and solvents

- Tough weather resistant Urethane construction is lightweight and also high impact absorbing

- Simple to carry with Built-in and Molded-in carrying handles (no sharp or harsh edges)

- Optional Mounting Brackets available

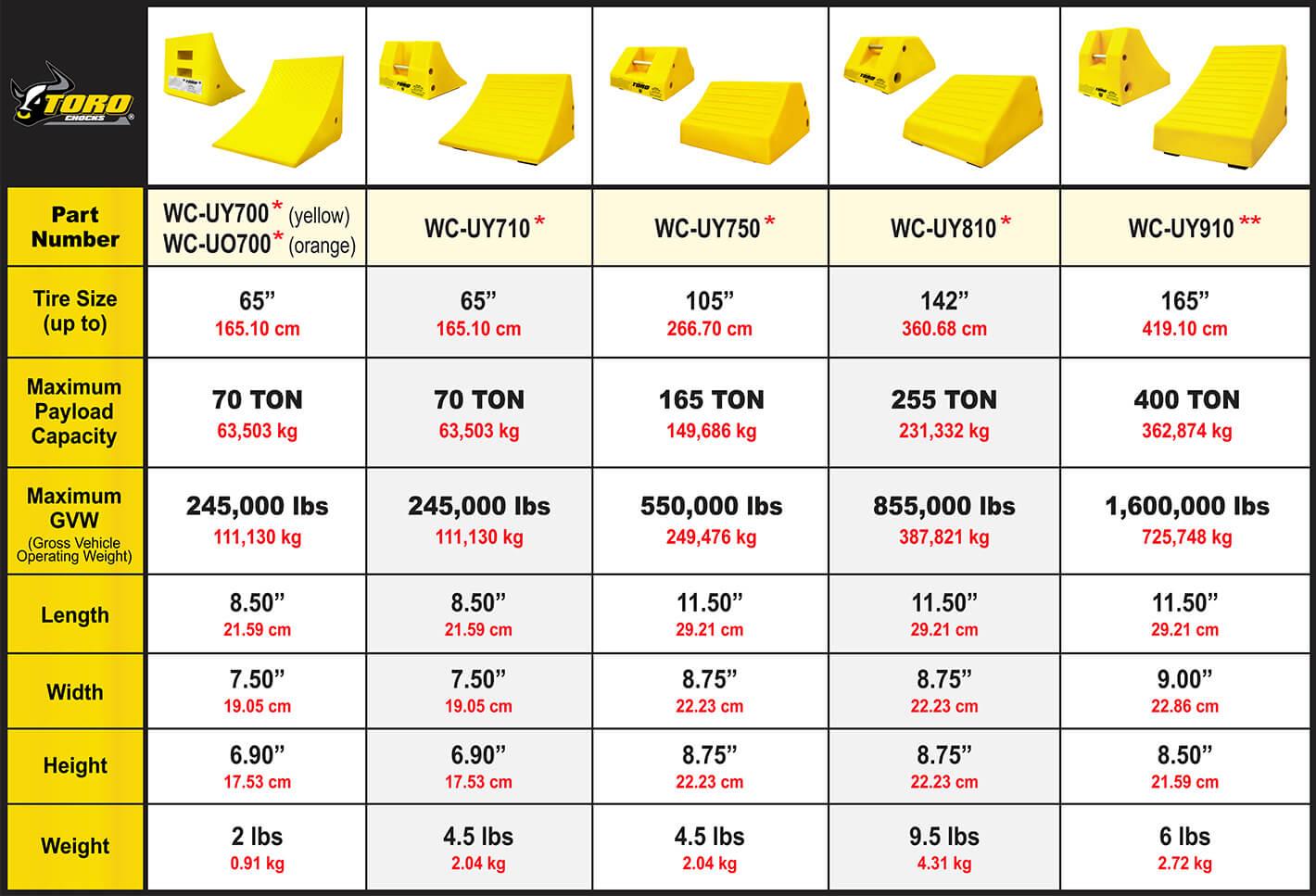

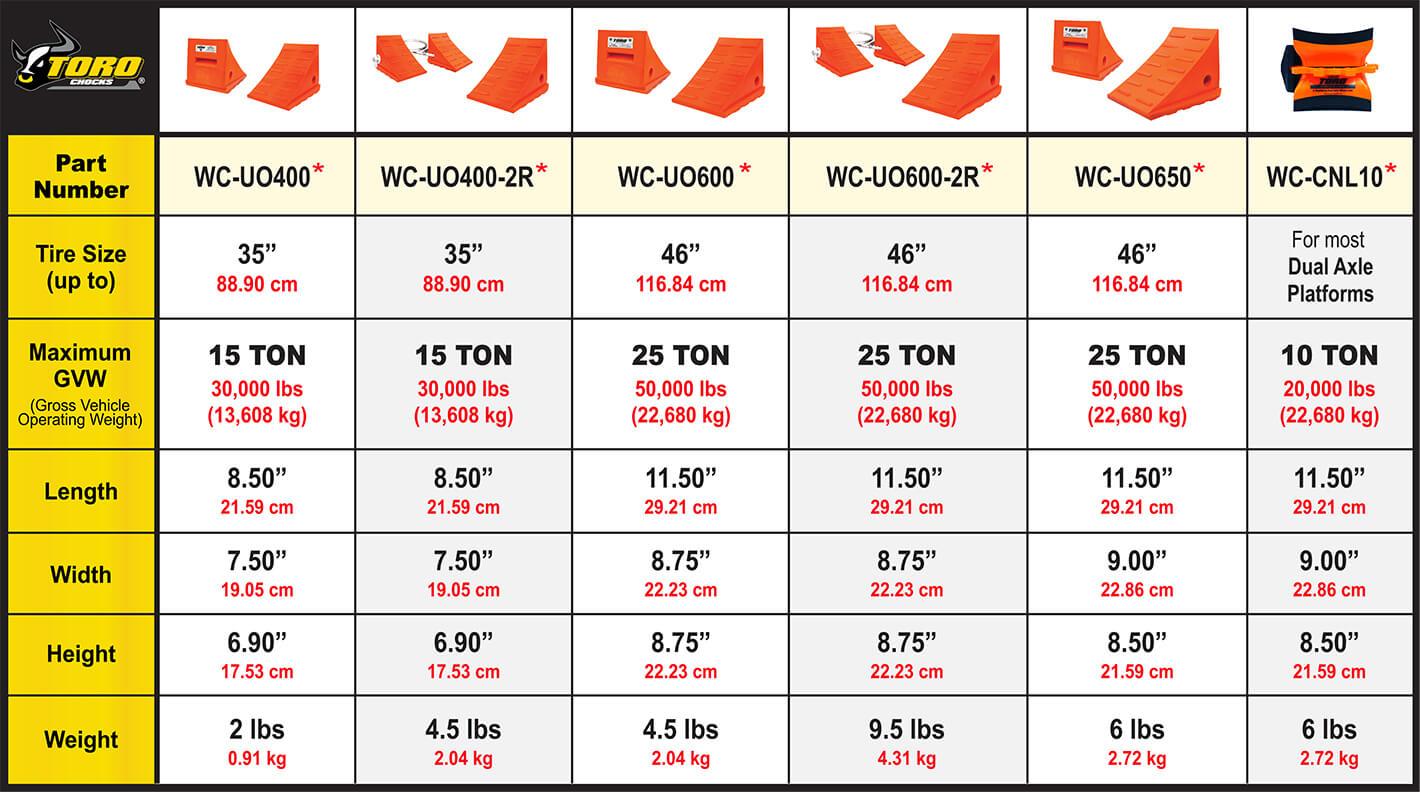

TORO® Wheel Chocks – Wheel Chock Reference Guide

Driver Industrial Safety™ tests and certifies

our wheel chocks to provide an easy

to use Wheel Chock Reference Guide.

To make use of this reference guide:

- Choose your wheel chocks based on the Maximum Gross Vehicle Operating Weight (with payload) and Tire Size (or Tire Diameter) of the vehicle

- Our Wheel Chock Reference Guide was derived using testing results which are based on being used on the wheel chocks at an 8% grade

- Numerous varying aspects occur, it is necessary for each end user to test wheel chocks for each application.

Heavy Equipment Wheel Chocks

* minimum of (2) chocks required

** minimum of (4) chocks required

General Purpose Wheel Chocks

Various Colors Available for General Purpose Series Chocks Upon Request!

(excluding WC-CNL 10)

Testing & qualification is required for individual vehicles and for correct product selection to meet site requirements.

Advised GVW is a guide only. This will vary due to environmental factors. Please complete an adequate risk assessment before using chocks. Do not use chocks if chocks are damaged.

Wheel Chock Mounting Brackets

For our 15 Ton, 25 Ton, and 35 Ton General Purpose Wheel Chocks we offer both Heavy-Duty Vertical and Horizontal mounting brackets. The vertical orientation helps ensure quick removal and return of wheel chocks, while the solid 16-gauge stainless steel material safeguards the bracket from corrosion. Mounting Bracket hardware NOT included.

General Purpose : TORO® WC-BKT6 Vertical Mounting Bracket

(For use with TORO® wheel chock series WC-UO600 and WC-UO650)

**Use WC-BKT4 Mounting Brackets with TORO® wheel chock series WC-UO400**

For our 70 Ton, 165 Ton, 255 Ton, and 400 Ton Heavy Equipmet Wheel Chocks we offer a Heavy-Duty Horizontal Universal Dual mounting bracket that holds (2) wheel chocks at a time. Strong, durable structure allowing the user to confidently mount to the rear or sides of the heavy equipment vehicle. Mounting Bracket hardware NOT included.

Advantages of using Driver Industrial Safety’s TORO®

Wheel Chocks

Your vehicle, environment, payload, and your maximum Gross Vehicle Weight (GVW) will determine the type of wheel chock for your application. See our Chocking Procedures for land vehicle use which provide Chocking Diagrams to provide end users with direction on positioning chock on either uphill, downhill or level grade placement of chocks for various applications on vehicles or heavy equipment such as vehicles with 2 or more axels, articulated trucks, trucks up to 255 tons, and trucks over 255 tons.

Advantages:

-

We are a leading wheel chock manufacturer!

- Driver Industrial Safety™ makes a wheel chock for almost all styles of tire-based vehicles

- We offer a widespread of wheel chocks, tonnage high enough for the extremely tough mining sector

- TORO® Wheel Chocks are made of a very durable urethane with a product life span which results in cost savings

- Urethane wheel chocks are exceedingly lightweight in comparison to their heavily weighted steel and aluminum equivalents

- Urethane wheel chocks are robust and are able to resist harsh weather conditions, oils, solvents, tears, and abrasions

- TORO® Wheel Chocks are designed to ensure there is no harsh damage to your vehicle’s tires

- Superior High Visibility safety colors* are stocked and used (*custom colors are also available for job assignments and site management)

- Driver Industrial Safety’s TORO® Wheel Chocks comply with multiple industry safety standards such as MSHA (Mine Safety and Health Administration), OSHA (Occupational Safety and Health Administration), NFPA (National Fire Protection Agency), DOT (Department of Transportation), SAE (Society of Automotive Engineers), and ANSI (American National Standards Institute)

- Recessed Molded-in or Built-in carrying handles

- Mounting brackets available